Safety & Respectful working atmosphere

Protecting health and safety in the workplace is particularly important to us, and is ensured through training and preventive measures. We care about our employees and create a pleasant and respectful working atmosphere.

Society

Entrepreneurial success and social responsibility go hand in hand. We engage with a wide range of stakeholders. We manufacture safe, high-quality products and rely on long-term partnerships. With our production site located in a rural area, we provide skilled jobs and contribute to the development of the regional economy. Our social commitment also focuses on local projects and an active involvement in the associative fabric of our region. Our ethical, legal and responsible behaviour is defined in the Südzucker Group's code of conduct.

Greenhouse gas savings

We are striving to reduce greenhouse gas emissions throughout the value chain. The renewable ethanol produced here for use in transport is already saving an average of more than 78% in greenhouse gas emissions compared with fossil fuels.

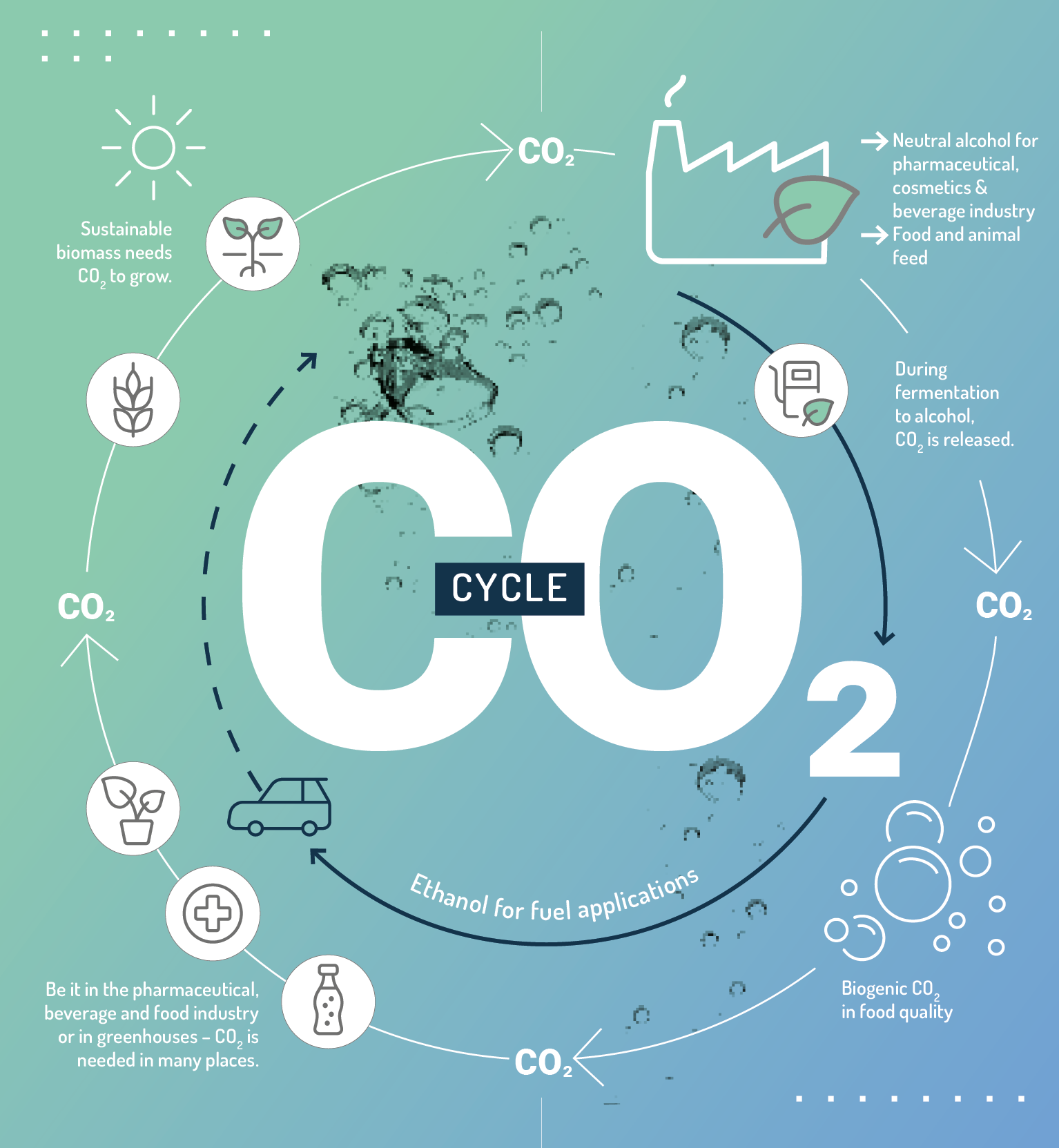

Circular economy

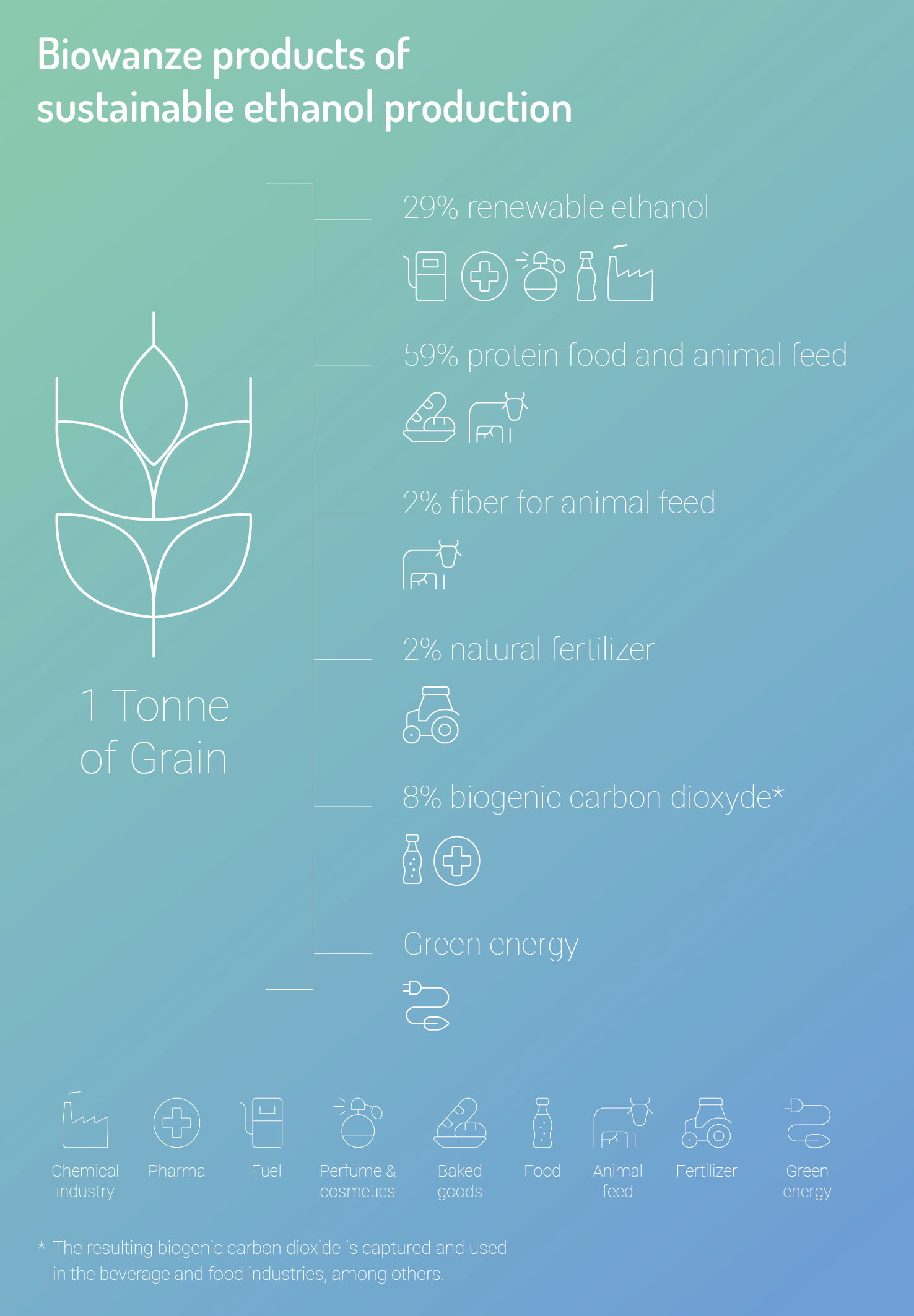

Our biorefinery works according to the principle of the circular economy, using sustainable raw materials as much as possible. By using biomass as a fuel and raw material, we can supply the Belgian and European markets with numerous products that reduce greenhouse gas emissions. These include renewable fuels, but also foodstuffs, natural fertilisers, green energy and animal feed, the latter contributing to Europe's protein supply and reducing soya imports from North and South America.

Raw materials

Biowanze only uses agricultural raw materials that are mainly of European and Belgian origin, taking into account all quality and sustainability requirements. Agricultural raw materials must not be grown in protected areas, such as forests or areas with a high level of biodiversity.

Energy

90% of the energy produced and consumed on our site is green, derived from certified renewable and local biomass. Thanks to 2 biomass boilers, high-efficiency cogeneration and continuous optimisation, Biowanze produces the electricity and steam needed to run the entire plant. Our vision: climate-neutral production by 2030.

Logistics

Even when purchasing and delivering our products, CO2 emissions must be kept as low as possible. This is made possible by short transport routes using local raw materials, and the ideal location of our production site along the railways and the Meuse river.

Sustainable management, i.e. reconciling ecology, economy and social responsibility, is a central element for CropEnergies. This goes hand in hand with the vision of safeguarding the well-being of present and future generations.

The biowanze model aims to contribute to the development of a sustainable circular economy for its region, the agricultural sector and the fight against climate change. Sustainability applies at all levels: social responsibility, supply chain, optimising energy use, distributed products and developing green technologies.

Renewable local raw materials are completely processed into products with high added value in order to save resources and avoid waste.

BioWanze provides immediate and sustainable mobility solutions through the production of renewable ethanol, but that's not all. BioWanze's range of products, including food products, livestock feed, green fertiliser, innovations and green energy production, enable the creation of a truly circular ecosystem based on biomass and local raw materials.

In the "Renewable Energies Directive", the EU stipulates sustainable certification of the entire value chain: seamlessly, from raw material extraction to production and delivery. All our ethanol plants are certified as sustainable under at least one of the certification systems recognised by the EU and are audited annually.

Since the site was launched, our biomass boiler - the only one of its kind in the world - has been producing the electricity and steam needed to run the entire plant. As the bran (the outer husk of the wheat) is not used in the bioethanol production process, we recover it and feed it into our biomass boiler.High-efficiency cogeneration enables us to produce more green electricity than we need to satisfy our consumption. The surplus supplies the Wanze sugar refinery outside the countryside and the CO2 liquefaction site, while the balance is fed into the public grid.

From 2021, biowanze is taking another step towards carbon neutrality by building a 2nd biomass boiler fuelled by wood chips.90% of the energy consumed on the site is green, derived from certified renewable and local biomass. The proportion of fossil energy consumed (natural gas) has fallen from 35% to 10%.

Biowanze favours a short supply radius. Subject to strict selection criteria, the feed wheat comes exclusively from Belgium (50%), France and Germany.The biomass used for the 2nd boiler comes from within a 250km radius of the production site.

In the "Renewable Energies Directive", the EU stipulates sustainable certification of the entire value chain seamlessly of biomass used for green power. All biomass (solid, liquid and gaseous) used on Biowanze site are certified as sustainable under at least one of the certification systems recognised by the EU and are audited annually.

The biowanze model aims to contribute to the development of a sustainable circular economy for our region and the agricultural sector, and to the fight against climate change.

In the "Renewable Energies Directive", the EU stipulates sustainable certification of the entire value chain: seamlessly, from raw material extraction to production and delivery. All our ethanol plants are certified as sustainable under at least one of the certification systems recognised by the EU and are audited annually.

| Certification systems | Company |

|---|---|

| 2BSvs | Ryssen Alcools SAS |

| ISCC EU | Ensus UK Ltd |

| REDcert EU | BioWanze SA, CropEnergies Bioethanol GmbH, Ryssen Alcools SAS |